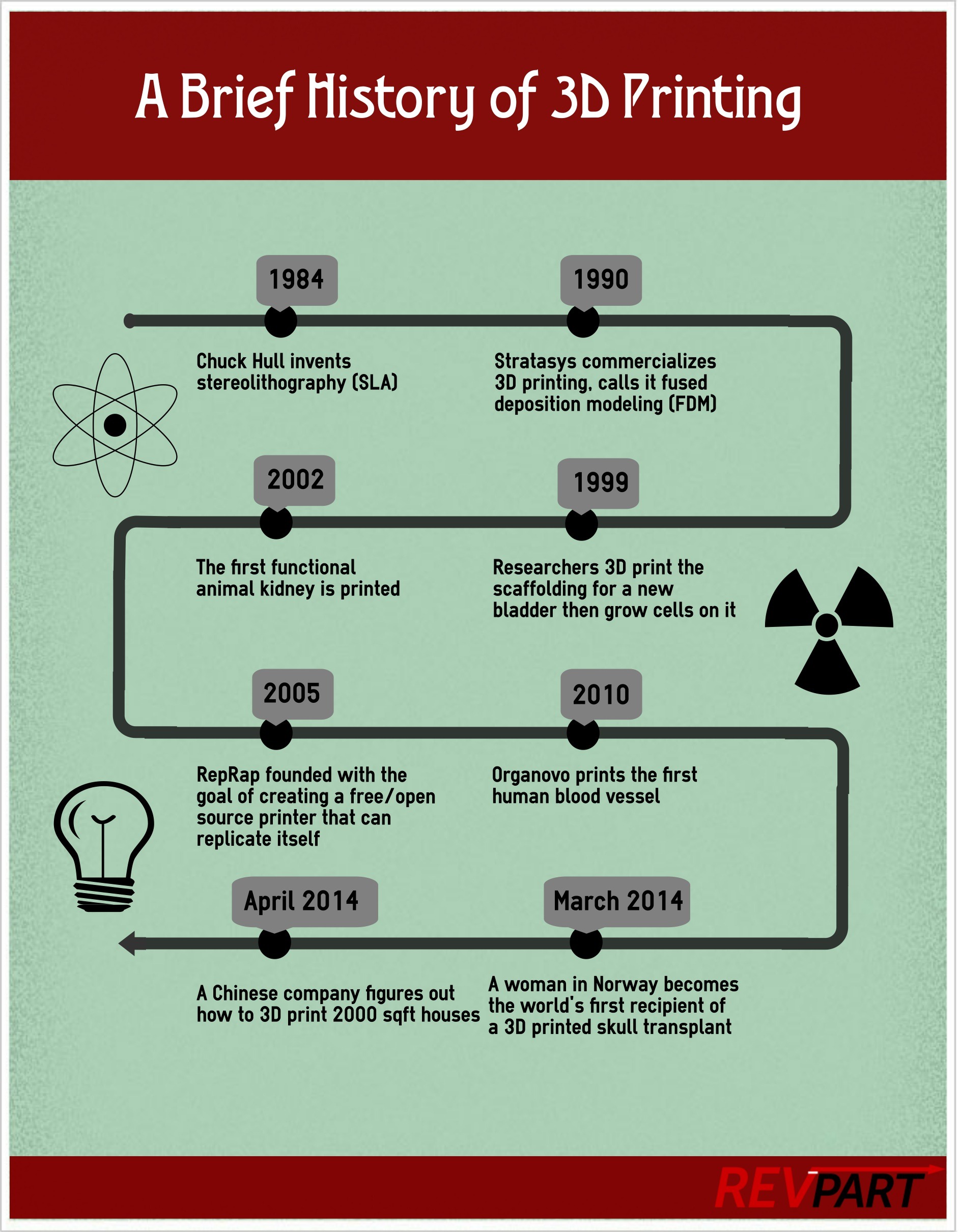

Materials like Carbon Fiber and Glass Fiber are now a regular print media. The Process is measured as upto to 10 times faster than SLS The processes of material recoating and agent distribution and heating are carried out by separate head arrays that move across the print bed in different directions, thus allowing the user to optimize both processes independently. The technology gets its name from the multiple inkjet heads that carry out the printing process. The company explains its technology is built on decades of HP’s investment in inkjet printing, jettable materials, precision low-cost mechanics, material science, and imaging. It is a powder bed fusion 3D printing technology. Now there are a variety of plastics and filaments that are widely available.Ī game changer arrived in 2016, Multi Jet Fusion from Hewlett Packard. The materials that printers use have also evolved. Along with the lowering prices, the quality and ease of printing also increased. In the 2010s, the prices of 3D printers started to reduce dramatically, making them available to the general public. Technology was now more available to new companies and competition, hence allowing the price of 3D printers to reduce and 3D printing to become more accessible. In 2008, the first prosthetic leg was printed, propelling 3D printing into the spotlight and introducing the term to millions across the globe. In 2009, the FDM patents filed in the 80s fell into the public domain, opening the door for innovation. But innovations were happening every day and new discoveries, methods, and practices were being refined and invented. They were difficult to use, expensive, and many of the final prints required a lot of post processing. CAD is a key tool in the process of creating a 3d printed component.ĭuring this time, the machines were very different from those that we use now. Through the 2000’s, many different CAD platforms became more accessible. Tthe first freely available SLS printer was released In 2006, changing the vision of designers and enthusiasts, creating real time demand manufacturing of industrial parts. In the 90s, many startup businesses were experimenting with the different additive manufacturing technologies. But, they are the three that serve as the building blocks that would lay the groundwork for the technology to grow and for the industry to be disrupted. These three technologies are not the only types of 3D printing methods that exist. FFF technology has gone on to become the most common form of 3D printing we see today. Scott Crump also managed to patent Fused Deposition Modeling (FDM) towards the late 80’s FDM, also called Fused Filament Fabrication (FFF), differs from SLS and SLA in that rather than using light, filament is directly extruded from a heated nozzle. This system fused powders, instead of liquid, using a laser.

In 1988, Carl Deckard at the University of Texas filed the patent for Selective Laser Sintering (SLS) technology. The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988. An American furniture builder who was frustrated with not being able to easily create small custom parts, Hull developed a system for creating 3D models by curing photosensitive resin layer by layer. In 1986 he submitted his patent application, and in 1988 he went on to found the 3D Systems Corp. He figured out a layer by layer approach for manufacturing, using a photosensitive resin that was polymerized by UV light. This being an early version of the modern day SLA machine.Ĭharles Hull, filed the first patent for Stereolithography (SLA).

In the early 80’s, Hideo Kodama was busy trying to develop a rapid prototyping system. The first documented evidence of 3D printing is traced to the early 1980s in Japan. The history of 3D printing, also known as additive manufacturing, maybe longer than you believe. Identified below is a chronological diary of events and possible future predictions for this technology going forward.

0 kommentar(er)

0 kommentar(er)